Lava or crater glazes can be a lot of fun, resulting in bubbling, textured finishes in cone 6 oxidation firings. The addition of silicon carbide will produce this result in just about any glaze, as the silicon carbide produces vapors as it reaches temperature.

If you want to mix these types of glazes, you’ll notice the recipes generally say “fine silicon carbide is best.” But what does that mean, exactly? There’s a whole range of silicon carbide grits out there, and many ceramic suppliers just carry one or two.

For this post, seven different grits of silicon carbide ranging from 60 grit (coarsest) to 800 grit (finest) were tested to see which produced the best lava- or crater-type bubbles in a cone 6 oxidation firing. They were tested in the Marilee’s Lava glaze at a 3.5% concentration of silicon carbide. (Many recipes list the silicon carbide in this glaze as 0.34, but I’ve seen enough others arguing that was originally a typo many years ago, so I went with the 3.5% recipe.)

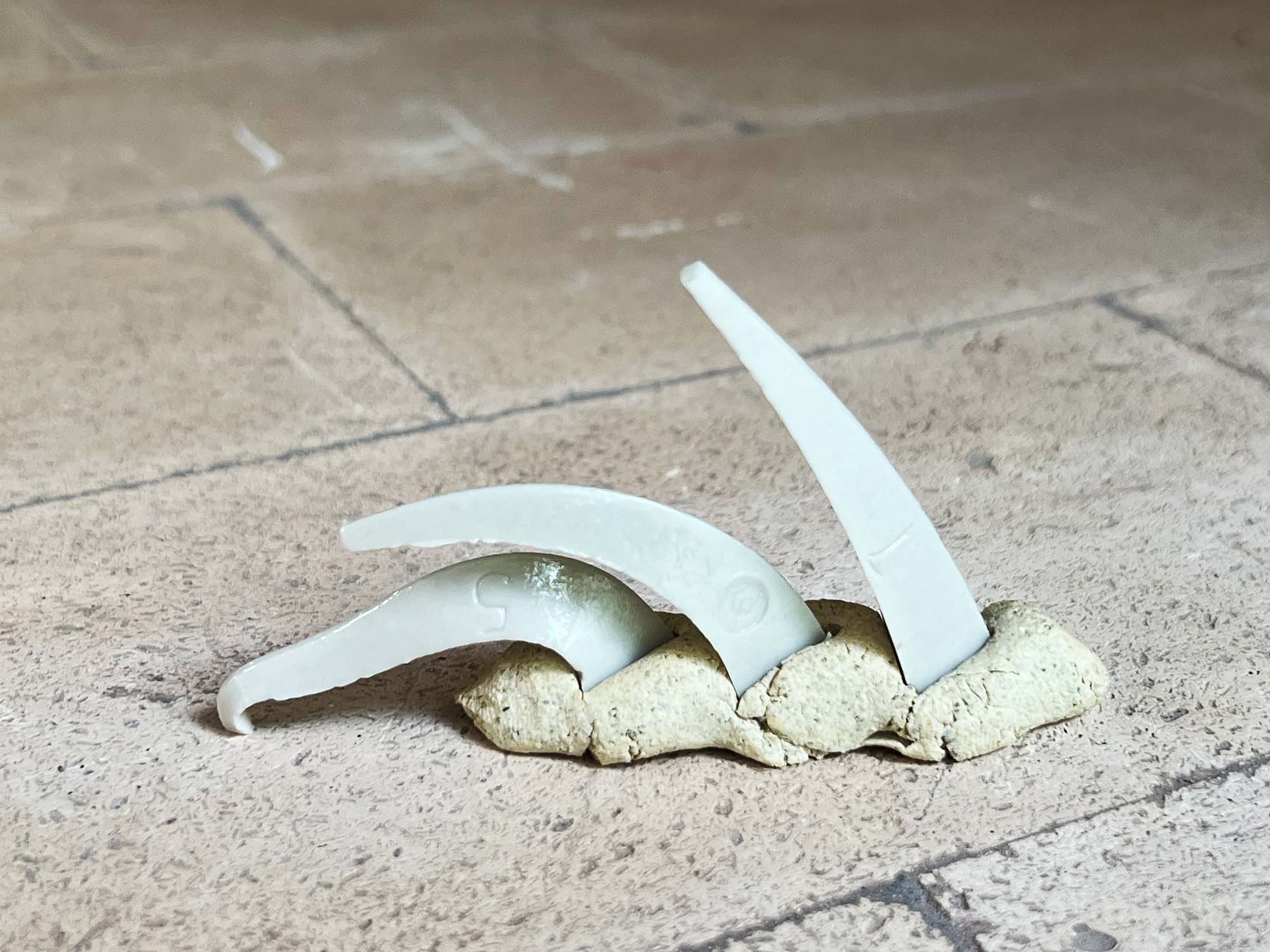

Note that excessive bubbling can cause small blister that break, crack, or produce sharp surfaces. It’s always best to test in your kiln. If excessive bubbling occurs, apply thinner coats of this glaze, or reduce the concentration of silicon carbide.

Table of Contents:

Intro

Marilee’s Lava Glaze Recipe

Results

Where to Buy Silicon Carbide

Test Tiles

Other Recommended Lava / Crater Glazes

Summary

Marilee's Lava (3.5% Silicon Carbide version)

| Ingredient | Percentage | 1000g batch |

|---|---|---|

| Custer Feldspar | 49.7 | 497g |

| Whiting | 23.9 | 239g |

| EP Kaolin | 13.2 | 132g |

| Silica | 13.2 | 132g |

| Add: | ||

| Titanium Dioxide | 11.3 | 113g |

| Silicon Carbide | 3.5 | 35g |

Results

Going in to these tests, I assumed the finer silicon carbide was recommended because the rougher stuff resulted in even bigger bubbling that might crack and break, but I couldn’t have been more wrong. The larger silicon carbide pieces (coarser grits such as 60 and 120) barely caused any bubbling. The 60 grit resulted in a pockmark texture that is interesting, but definitely not lava or crater. The sweet spot seemed to be 400 grit, if you want big, flowing lava effects. At 800 grit, there was still great bubbling but surprisingly to me, the silicon carbide is so fine that it results in less of the grey discoloration so often found with this material.

Overall, I found all the results interesting and these will help me fine tune my glazes, and I hope yours too. Test tile images for all grits are posted below.

Where to buy Silicon Carbide

The silicon carbide used in these tests was purchased at HIS Glassworks in North Carolina.

Your local ceramic supplier most likely carries silicon carbide, but many just have one or two grits.

Or check out suppliers on Amazon. There are a few, including a kit with a selection of grits designed for rock polishing.

Test Tiles

The first group of images shows the range of glaze results with the different silicon carbide grits.

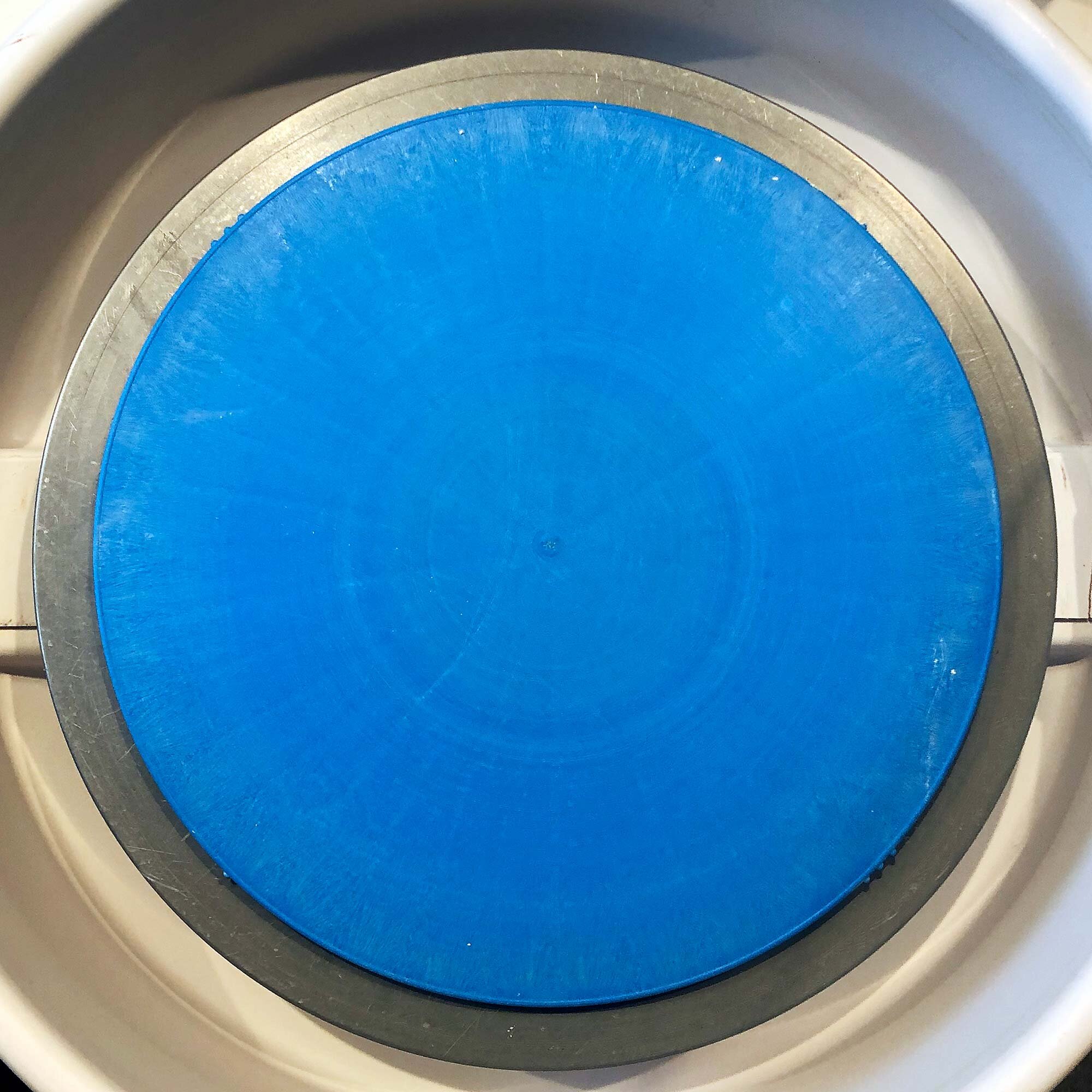

Vertical test tiles of Marilee’s Lava Glaze fired to cone 6 oxidation (medium speed firing). The bottom shows one dip, while the top has a second dip.

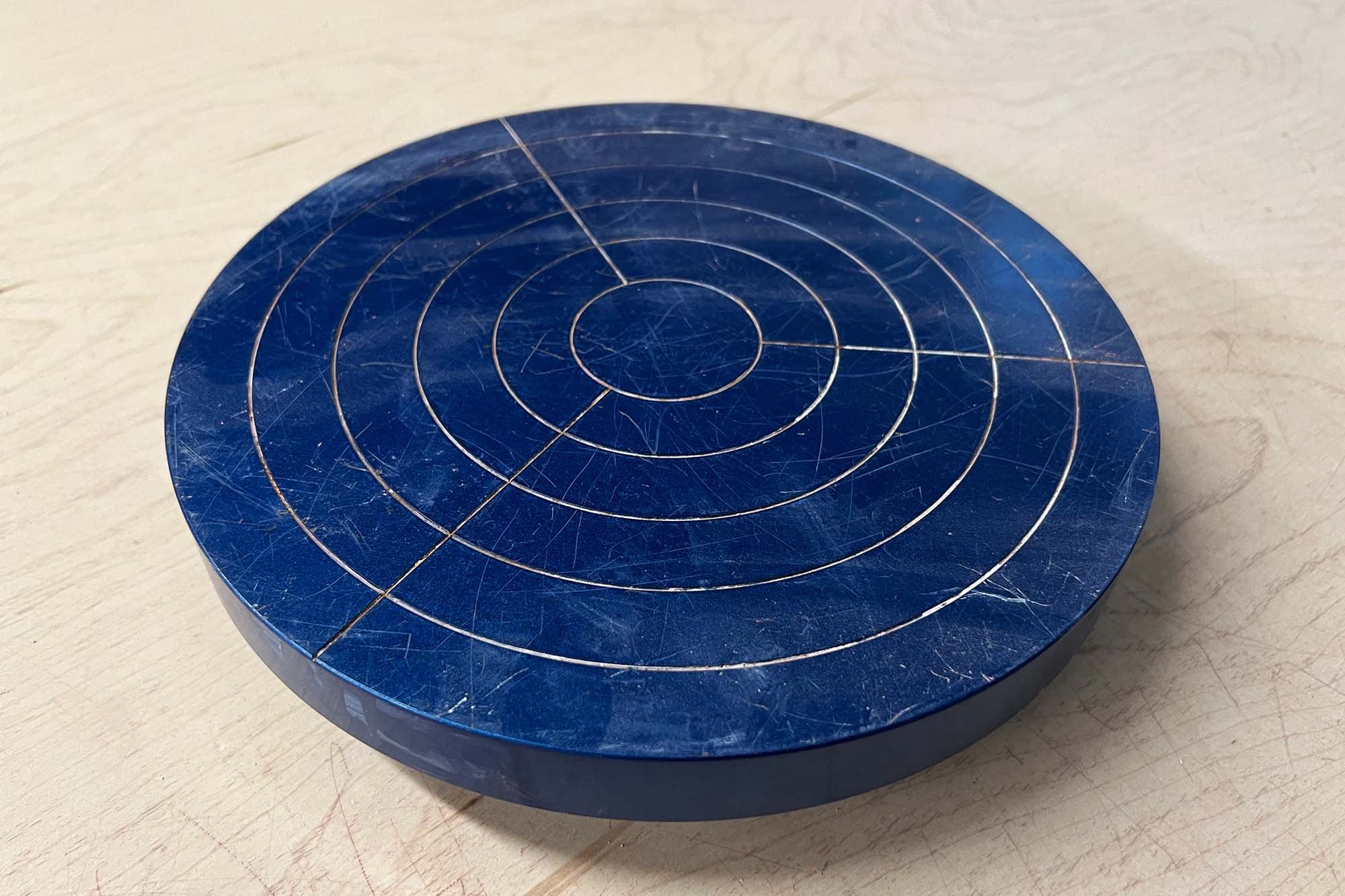

Test tiles fired horizontally with the same range of silicon carbide grits. Top half has a second dip.

The horizontally-fired test tiles at an angle to show some of the texture. There is virtually no lava / crater effect with coarser grits.

60 Grit Test Tiles

60 grit vertical test tile

60 grit vertical and horizontal test tiles

60 grit vertical and horizontal test tiles

120 Grit Test Tiles

120 grit vertical test tile

120 grit vertical and horizontal test tiles

120 grit vertical and horizontal test tiles

220 Grit Test Tile Images

220 grit vertical test tile

220 grit vertical and horizontal test tiles

220 grit vertical and horizontal test tiles

320 Grit Test Tile Images

320 grit vertical test tile

320 grit vertical and horizontal test tiles

320 grit vertical and horizontal test tiles

400 Grit Test Tile Images

400 grit vertical test tile

400 grit vertical and horizontal test tiles

400 grit vertical and horizontal test tiles

600 Grit Test Tile Images

600 grit vertical test tile

600 grit vertical and horizontal test tiles

600 grit vertical and horizontal test tiles

800 Grit Test Tile Images

800 grit vertical test tile

800 grit vertical and horizontal test tiles

800 grit vertical and horizontal test tiles

Other Recommended Lava / Crater Glazes

There are a wide variety of lava / crater glazes and even underglazes but here are a few others recommended for cone 6 oxidation:

Akiko’s Crater Glaze (view recipe on glazy.org)

Pinell’s Strontium Crater (view recipe on glazy.org and also here. Also a few color tests here.)

Summary

This post covered tests of seven different silicon carbide grits in Marilee’s Lava glaze fired at cone 6 oxidation in a medium-speed electric firing. The best lava / crater results were with 400 to 800 grit, but all the results were interesting and might prove valid for future glaze research or application on sculptural pieces.

Lava and crater glazes are a great textural option for glazing in cone 6 oxidation. Due to the uneven glaze surface, they are not recommended for food service but can be used on the outside of pots or sculptural pieces.

If you enjoyed this post, you might enjoy the review of the glaze book Special Effects Glazing. If you are looking for a comprehensive introduction to glazing, the best book to start is John Britt’s Complete Guide to Mid-Range Glazes. Shop the book at amazon or bookshop.org.

What lava or crater glazes do you use in your studio? Let us know in the comments. Happy glazing!