Sandpaper ripped into eight pieces.

Sandpaper is a great studio tool but you usually don’t need to use a whole sheet at once. This tutorial will cover how to easily rip sandpaper into eight even pieces that are useful for small jobs such as sanding pottery ware, cleaning up rough wood, or any job. It’s a simple technique that results in even, rectangular pieces.

If you are doing any studio task that create dusts, wear a good dust mask or respirator. (Read our guide here) Or if you can, sand wet so that no dust is created.

For a guide to sandpaper and abrasives, click here.

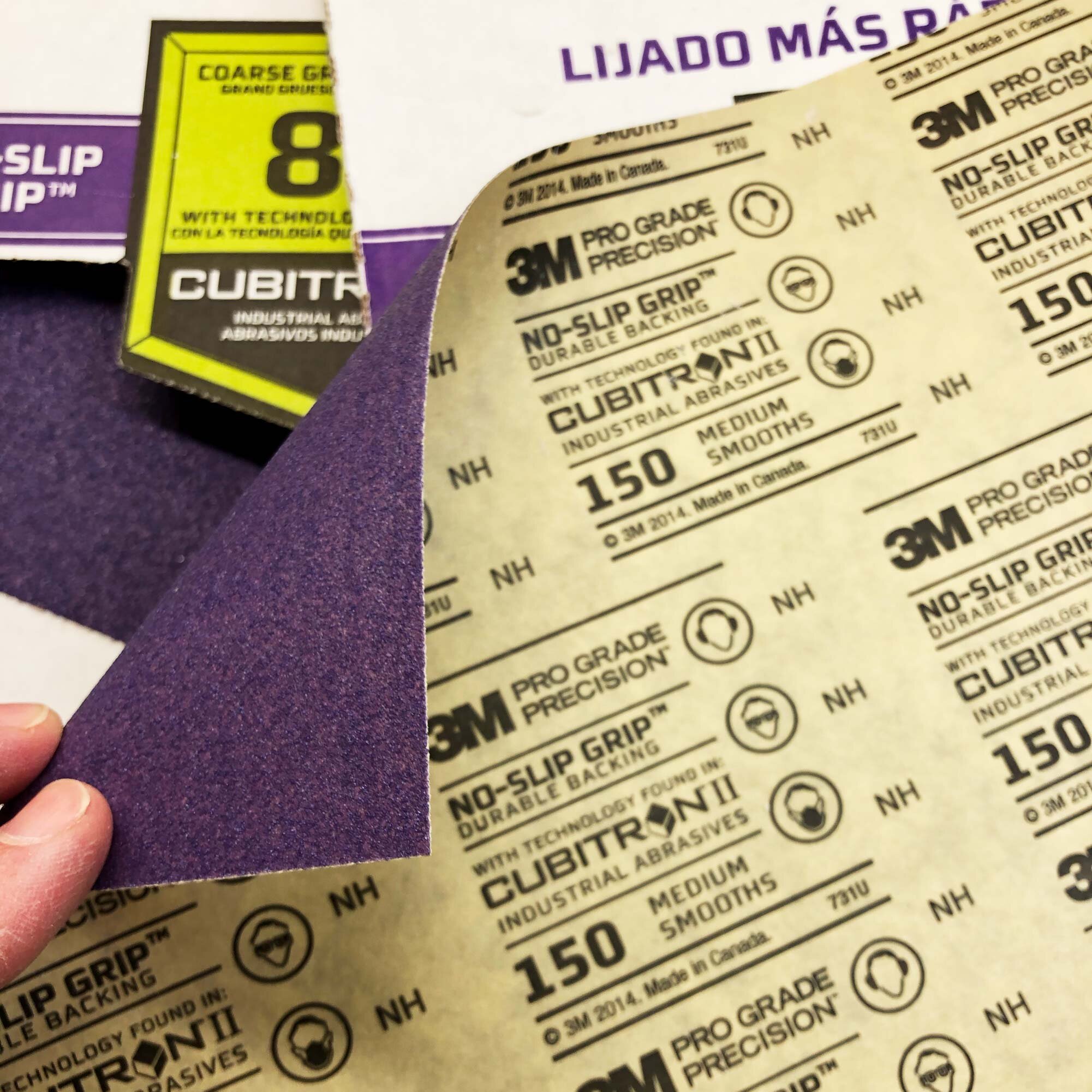

This tutorial uses 3M Pro Grade Sandpaper. It’s plastic backed, making it longer-lasting and suitable for wet sanding. It’s the best for ceramics and just about any other art studio use. Look for the “no-slip grip” sandpaper.

For sandpaper grits, I like to stock 60 and/or 80, 120, 200, and 400 grit.

How to Rip Sandpaper Into Smaller Pieces

Here’s how to rip a sheet of sandpaper into eight even pieces.

Step 1

Starting with a full sheet of sandpaper, fold it in half vertically (the long side) and crease.

Full sheet of sandpaper

Fold in half

Step 2

Rip along the crease

Then, rip the sheet in half along the crease. You may rip a bit unevenly at first, but with practice you will get an even rip.

Ad

Step 3

Then on the long side of the smaller pieces you have just made: fold, crease, and rip.

Fold, crease, and rip again

Square pieces might be useful, but we’ll keep going.

Step 4

Continue to fold pieces in half, crease, and rip. I find that ripping a sheet into eight sheet results in a useful size.

ad

Step 5

Sandpaper ripped into eight pieces.

When you are at eight rectangular pieces, you are set. Now, find a small cup or box to store them in.

Summary

What sandpaper do you use in your studio? How do you rip and store it? Let us know in the comments.

You might enjoy:

Complete Guide to Sanding and Abrasives for Ceramics and Pottery

Best HEPA Vacuum for ceramics and woodshops

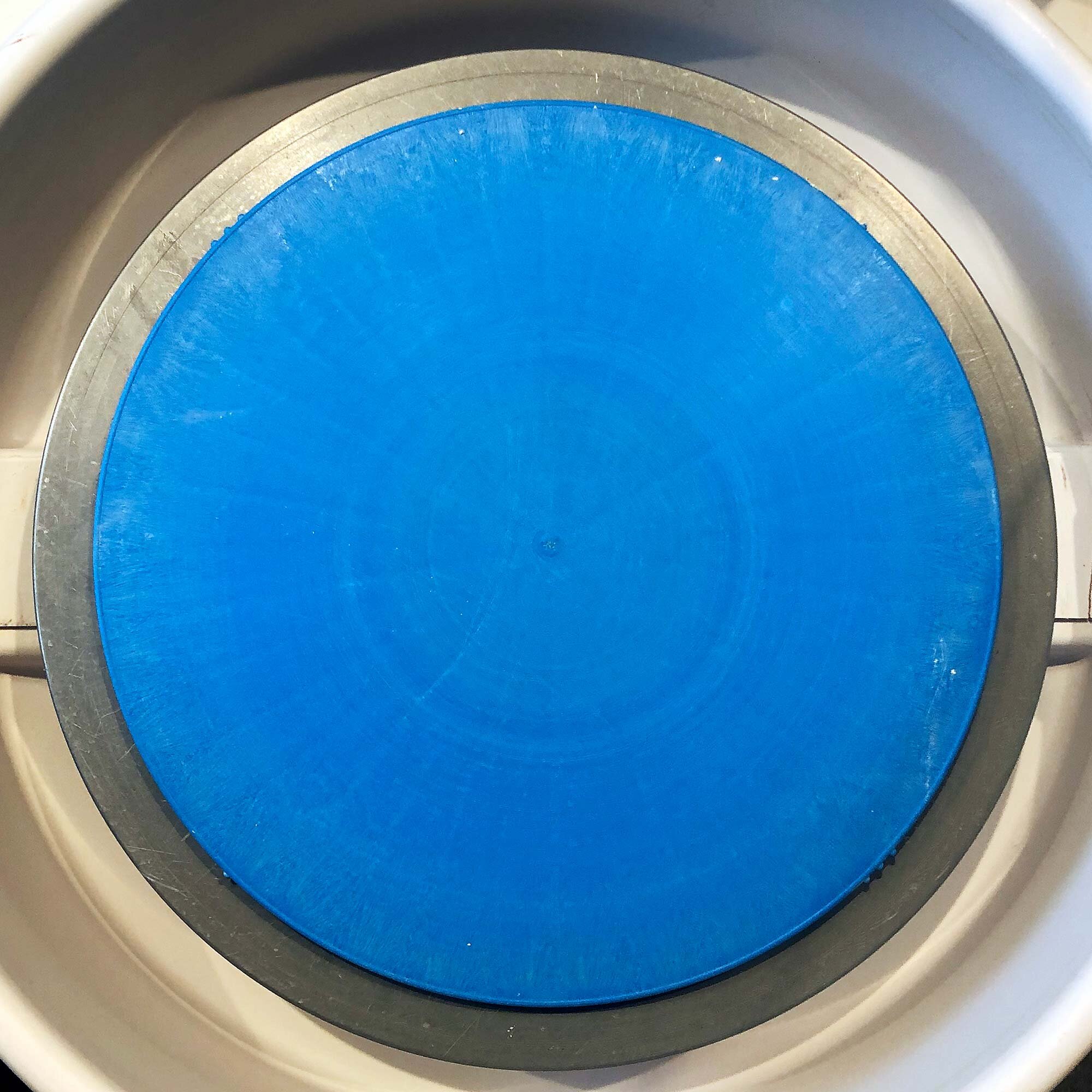

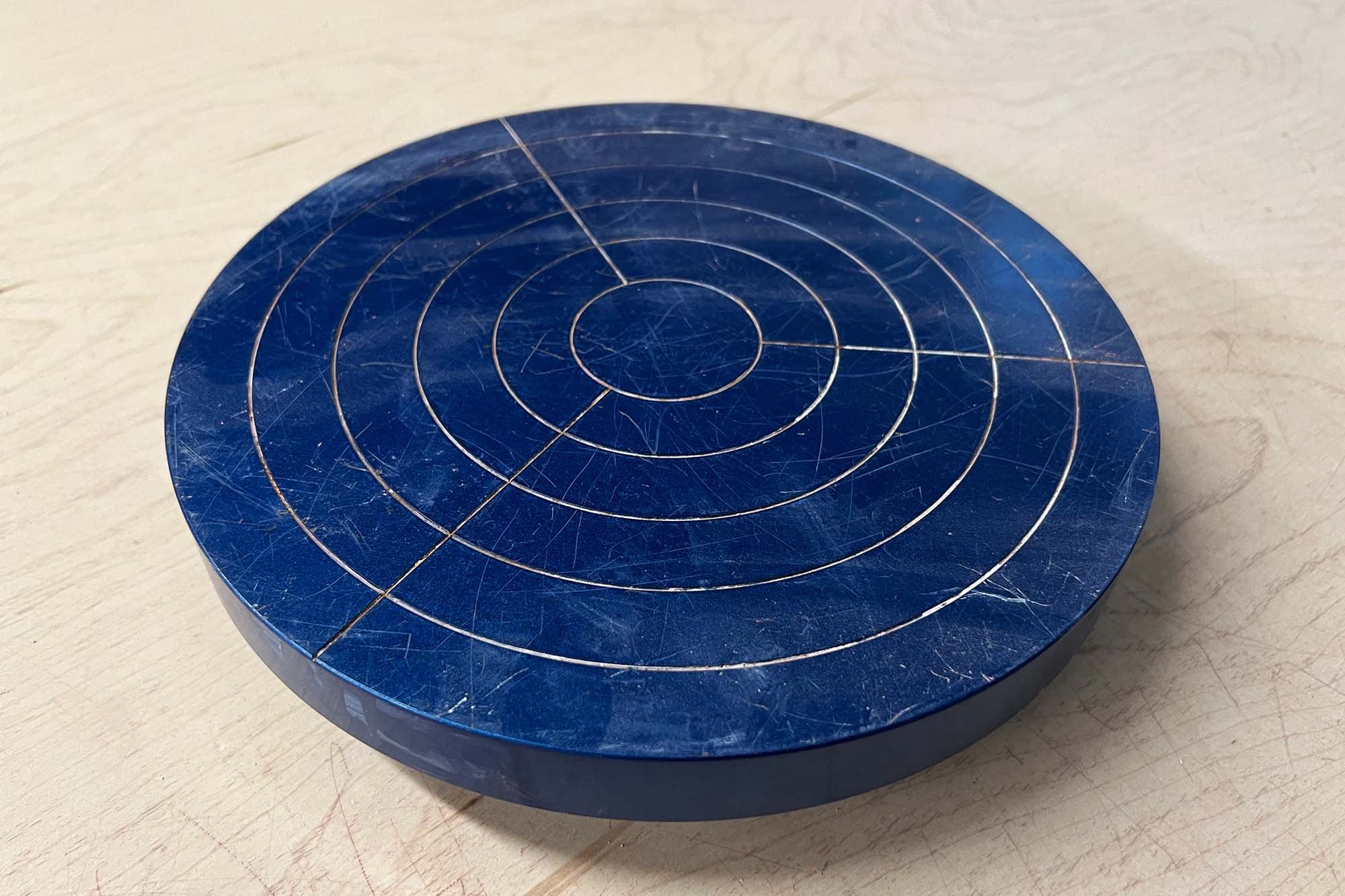

How to Make an Interchangeable Grinding Disc for Your Pottery Wheel

Shopping links: