A diamond-coated grinding disc is a great way to transform your pottery wheel into a grinding and polishing workhorse. All you need is a grinding disc, bat, and velcro. This DIY system is designed for interchangeable discs, giving you the flexibility to grind at 60 or 120 grit, and even finer.

Useful in any ceramics or pottery studio, grinding discs give you an easy way to clean up glaze drips, smooth the bottom of pots or kiln posts, and best of all, they make use of something you probably already have in your pottery studio: a wheel. Paired with a bit of water from a sponge, you will have a dust-free grinding disc that is similar to a lapidary wheel for grinding glass.

This tutorial will cover how to make your own interchangeable grinding disc using industrial velcro. This allows you to use different grits, and change them out on just one bat. To get fired ceramic super smooth, I like to start at 60 grit, then 120, 240 and finish with 400.

Here’s what you’ll need:

> Scissors

> Industrial Velcro

> Grinding Disc

8” Grinding Disc from Diamond Core Tools

8” Grinding Disc from Uxcell

> Waterproof bat such as an Amaco Plasti Bat

A note on grinding discs:

The Diamond Core grinding discs are really high quality, long lasting, and wonderful to use. They cost around $50 each and come with an adhesive backing. You may find one grinding disc is the way to go, in which case, I would get one high-end disc and use the adhesive to attach it to a bat.

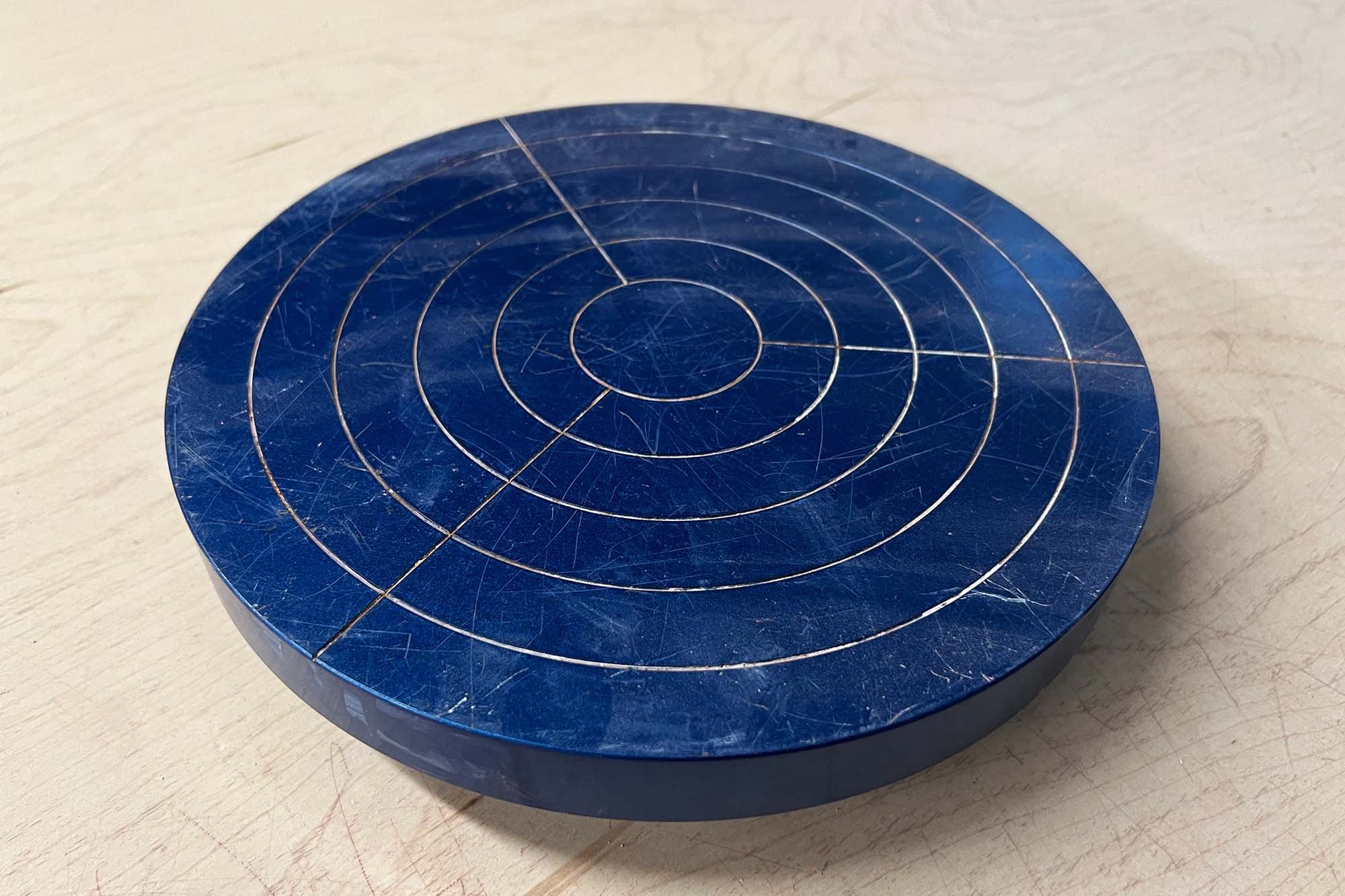

The Uxcell grinding discs found on Amazon and other sites are generics, have a middle arbor hole, and don’t last as long. But, they are perfect for this DIY system as you can buy multiple grits and change them out on one bat using the Velcro. And depending on your situation and needs, you can find generic grinding discs in a range of sizes, from 6 to 12 inches wide. A small 6 inch disc might just be perfect for a small studio where you just need to grind foot rings or small pieces.

Here’s some closeups of the 8” 120 Grit Uxcell grinding disc used in this tutorial. Click to enlarge:

How to Make a DIY Grinding Disc

Step 1

Step 1: Gather your materials

Gather your materials. You’ll need:

Diamond-coated grinding disc

Industrial Velcro

Scissors

Waterproof bat

Step 2

Step 2: Cut Velcro

Cut one side of the Velcro and attach to the backside of the grinding disc.

Note: you can probably use 1/3 to 1/2 of what I used here!

Step 3

Step 3: Cut other side of velcro

Cut the other side of the velcro to roughly match.

Step 4

Step 4: Attach velcro to grinding disc and bat

Peel of the backing and attach the Velcro to your bat.

That’s it! You have a new diamond coated grinding disc. Time to get grinding!

Step 5

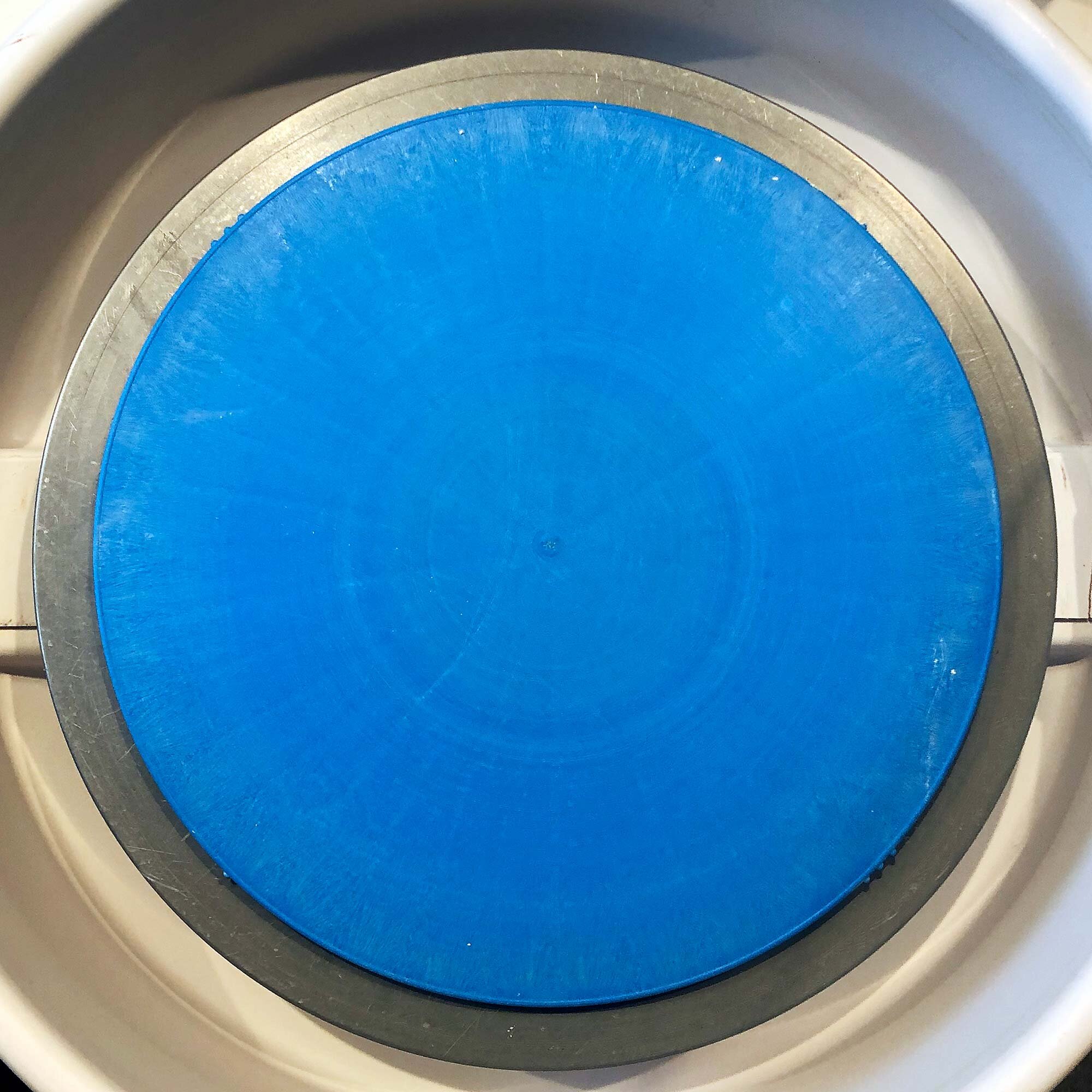

Step 5: Ready to grind

Test your diamond grinding disc. You’ll just a need your wheel, bat pins, and a sponge and water.

As you can see from the pic at right, the Industrial Strength Velcro does create a small gap between the grinding disc and the bat.

When using, we periodically sponged fresh water over the entire grinding disc. Used water in the splash pan was discarded.

Putting the Grinding Disc to Work

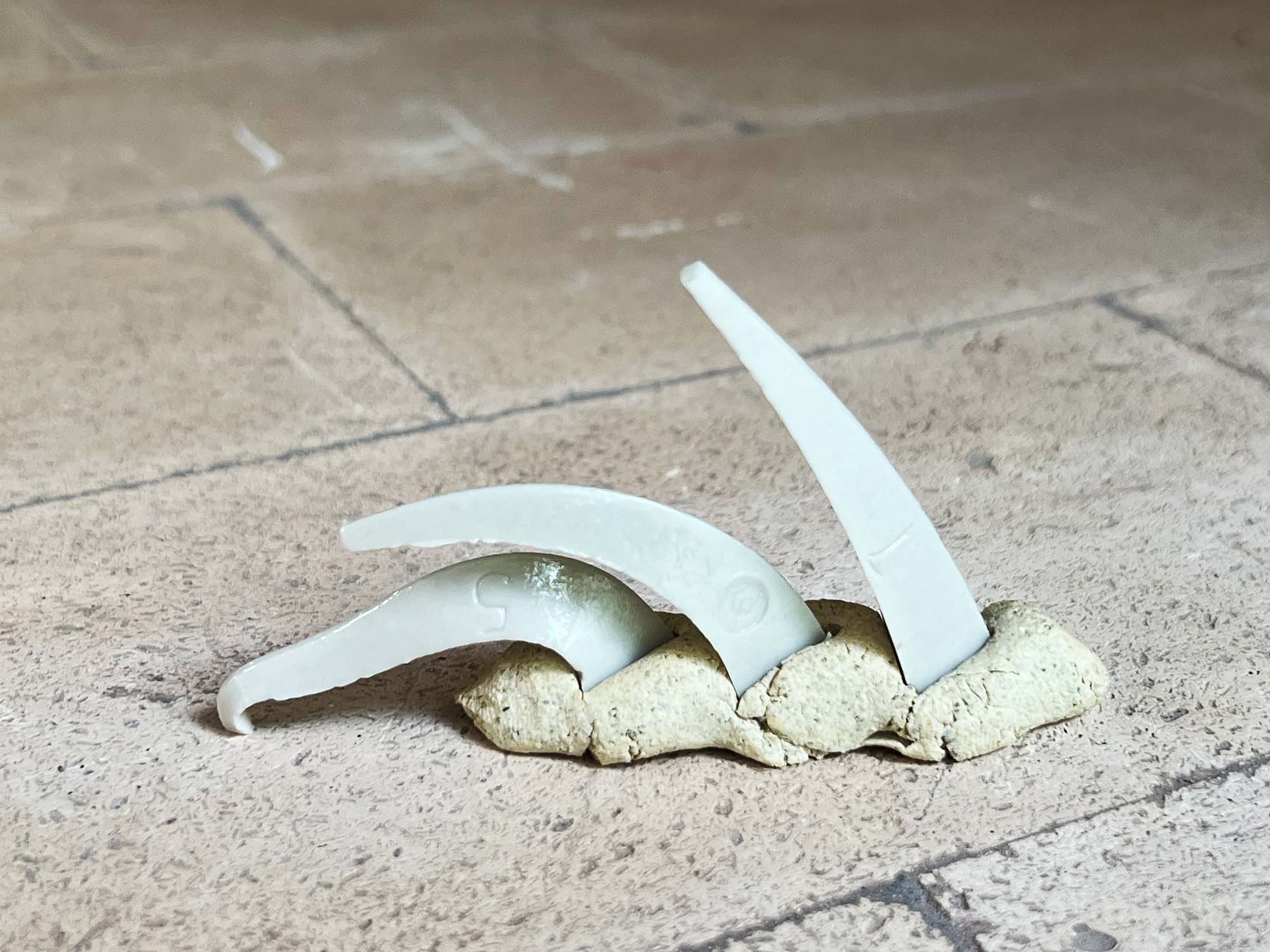

A dirty kiln post in need of grinding

The grinding disc made short work of the mess.

Summary

A diamond-coated grinding disc turns your pottery wheel into a grinding and polishing machine. This interchangeable DIY system gives you the flexibility to grind at a variety of grits. It’s a great addition to any studio.

Do you have any other ways of making grinding discs or transforming wheels into grinding machines? Let us know in the comments.

Check Amazon for prices on Industrial Strength Velcro, Uxcell Grinding Discs, and Amaco Plasti-Bats: